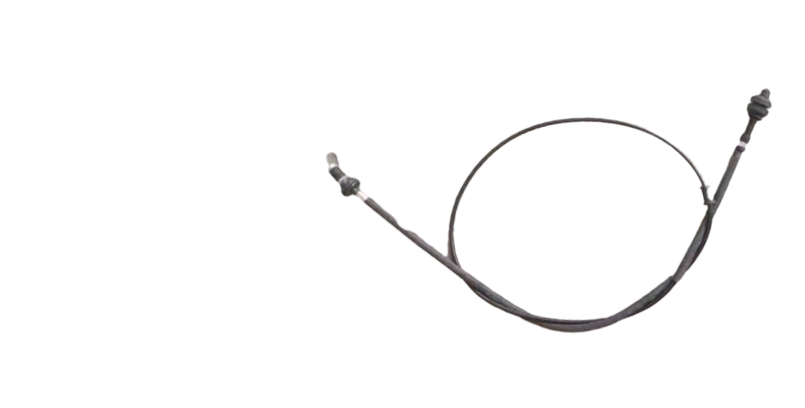

cable throttle pedal

The Evolution and Functionality of Cable Throttle Pedals

In the realm of automotive engineering, the throttle pedal plays a crucial role in determining a vehicle's acceleration and overall performance. Traditionally, cable throttle systems were the standard in cars. Although modern vehicles have largely transitioned to electronic throttle control systems, understanding cable throttle pedals remains essential for appreciating how far automotive technology has come and the persistent influence of mechanical systems in today's vehicles.

A cable throttle pedal system operates through a simple yet effective mechanical mechanism. When the driver presses the throttle pedal, it pulls a cable connected to the throttle body of the engine. This action opens the throttle plate, allowing air to flow into the engine. The more the driver presses the pedal, the wider the throttle plate opens, increasing the air-fuel mixture entering the combustion chamber, and consequently, the engine's power output.

One of the primary advantages of cable throttle systems is their direct and immediate response to the driver’s input. This mechanical linkage offers a tactile feedback that many performance enthusiasts appreciate. When the pedal is engaged, the driver can feel the connection between their actions and the resultant engine response, providing a level of engagement that can be somewhat lost in electronic systems.

However, cable throttle systems are not devoid of disadvantages. Over time, cables can stretch or become kinked, leading to inconsistent throttle response. Moreover, the physical mechanisms involved can introduce delays, especially when considering the possible wear and tear on components. These factors can lead to less precise control over the vehicle's power delivery, which may affect performance, particularly in high-performance or racing applications.

cable throttle pedal

Despite these challenges, many manufacturers have maintained cable throttle systems in specific vehicle models, especially in sports cars where driver engagement is paramount. These systems can also be simpler and less expensive to manufacture and maintain than their electronic counterparts. Furthermore, they do not rely on complex electronic sensors or the vehicle’s central computer, making them relatively straightforward in terms of repair and diagnostics.

The shift toward electronic throttle control began in the late 1990s and has since become the norm in most new vehicles. Electronic systems utilize sensors to detect the position of the accelerator pedal and relay this information to the engine control unit (ECU). The ECU then adjusts the throttle opening accordingly. This innovation offers advantages such as improved fuel efficiency, emissions control, and enhanced integration with advanced driver assistance systems.

Yet, the cable throttle pedal will always hold a place in automotive history, representing a simpler time in engineering. Car enthusiasts often express nostalgia for the days when mechanical systems reigned supreme, and direct driver involvement was commonplace. While the future points towards further electronic advancements—including capabilities like fly-by-wire systems—the lessons learned from traditional cable throttle pedals continue to guide automotive design principles.

In conclusion, the cable throttle pedal, while slowly becoming obsolete, illustrates the intricate balance between technology, performance, and driver experience in automotive design. As the industry evolves, the legacy of cable throttle systems will undoubtedly influence future innovations, ensuring that the essence of mechanical connection remains a key consideration in the ongoing development of vehicles.

-

Upgrade Your Vehicle with High-Quality Handbrake CablesNewsNov.01,2024

-

Optimize Your Bike's Performance with Quality CablesNewsNov.01,2024

-

Enhance Your Vehicle's Performance with Quality Clutch ComponentsNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality Throttle CablesNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality CablesNewsNov.01,2024

-

Affordable Solutions for Your Cable NeedsNewsNov.01,2024