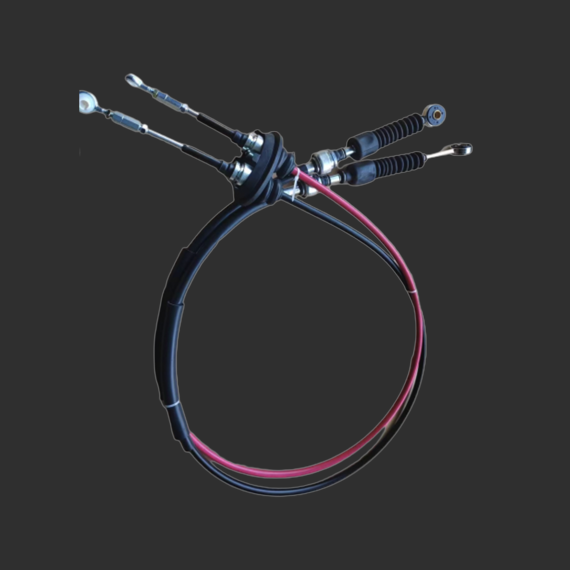

Connection Cable for Gear Linkage Systems in Automotive Applications

Understanding Gear Link Cables Significance and Applications

Gear link cables, crucial components in automotive and machinery applications, play an integral role in the transfer of gear shift movements from the gear selector to the transmission. By transforming the mechanical movement of the gear lever into the appropriate gear changes in the engine, these cables ensure optimal performance and smooth operation of vehicles and machinery. This article delves into the significance, construction, functionality, and maintenance of gear link cables, highlighting their indispensable role in modern transportation and machinery.

The Importance of Gear Link Cables

The primary function of gear link cables is to transmit the driver's intent to the vehicle's transmission system. When the driver shifts gears, this command must be effectively communicated to ensure that the engine operates at the desired power and speed. A well-functioning gear link cable can enhance driving experience, improve fuel efficiency, and ensure that the vehicle performs optimally. Conversely, a malfunctioning or worn-out cable can lead to shifting difficulties, increased wear on transmission components, and, ultimately, the potential for accidents or costly repairs.

In addition to automotive applications, gear link cables are equally critical in various types of machinery, including construction equipment, agricultural machines, and industrial machinery. These cables facilitate smooth operation and control, directly impacting productivity, efficiency, and safety in various work environments.

Construction of Gear Link Cables

A typical gear link cable consists of several key components that contribute to its functionality

1. Inner Core The inner cable is traditionally made of steel. This core takes the mechanical force from the gear lever and translates it into movement within the transmission system.

2. Outer Housing The outer housing is usually crafted from durable materials such as plastic or metal. This protective casing shields the inner cable from external elements, reduces friction during movement, and helps in minimizing wear and tear.

3. End Fittings These fittings connect the inner core to the gear shifter and the transmission. Proper alignment and attachment of these fittings are essential for the effective transmission of forces.

Functionality of Gear Link Cables

gear link cable

The operation of gear link cables hinges on their ability to convey movement accurately. When the driver shifts the gear lever, the inner core of the cable slides within its housing, pulling or pushing the respective end fitting. This action changes the place within the transmission system, allowing the vehicle to shift gears smoothly. The flexibility of the cable allows for various angles and orientations needed in compact engine compartments and intricate machinery setups.

Modern advancements have led to cable systems designed to withstand higher levels of stress and temperature fluctuations. Some systems incorporate materials with low friction coefficients, enabling smoother operation and prolonged lifespan.

Maintenance Practices

Given their critical role, regular maintenance of gear link cables is paramount. Here are some recommended practices

1. Visual Inspection Regularly check cables for signs of wear, fraying, or corrosion. Early detection of issues can prevent more severe problems later on.

2. Lubrication Applying lubricant to the inner core can help in reducing friction, improving the efficiency of motion transfer, and extending the cable's lifespan.

3. Adjustment Occasionally, cables may require adjustment to ensure optimal tension and alignment. Improperly adjusted cables can lead to premature wear and inefficient gear shifting.

4. Replacement If a cable shows significant wear or damage, timely replacement is essential. Using original equipment manufacturer (OEM) cables ensures compatibility and reliability.

Conclusion

Gear link cables are unsung heroes in the world of automotive and machinery engineering. They serve a fundamental purpose in ensuring that drivers can shift gears smoothly and efficiently. Understanding their construction, functionality, and maintenance is vital for anyone involved in vehicle maintenance or machinery operation. As technologies advance, gear link cables continue to evolve, promising even more reliability and performance in the years to come. Whether behind the wheel or operating heavy machinery, the seamless operation provided by these cables is integral to achieving a safe and efficient experience.

-

Upgrade Your Vehicle with High-Quality Handbrake CablesNewsNov.01,2024

-

Optimize Your Bike's Performance with Quality CablesNewsNov.01,2024

-

Enhance Your Vehicle's Performance with Quality Clutch ComponentsNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality Throttle CablesNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality CablesNewsNov.01,2024

-

Affordable Solutions for Your Cable NeedsNewsNov.01,2024