gear shift cable manufacturers

The Importance of Gear Shift Cable Manufacturers in Automotive Industry

The automotive industry is a complex web of components, each playing a crucial role in the overall functionality and performance of vehicles. Among these components, gear shift cables are essential for the smooth and reliable operation of transmission systems. These cables are integral for transferring the driver's input from the gear shift lever to the transmission system, enabling efficient gear changes. This article explores the significance of gear shift cable manufacturers and their impact on the automotive industry.

Understanding Gear Shift Cables

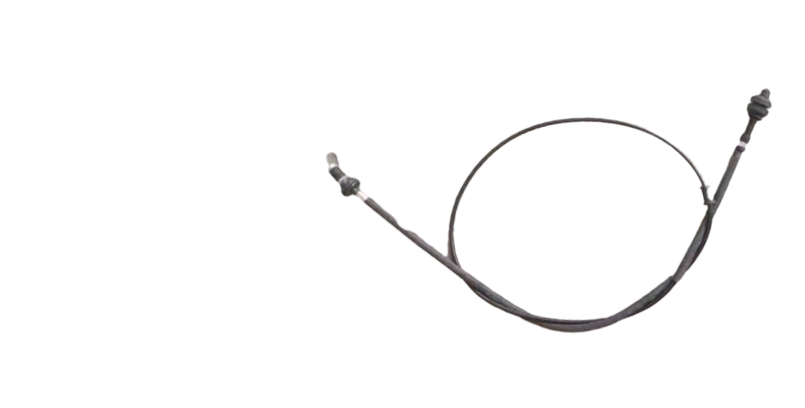

Gear shift cables are typically made of high-strength materials designed to withstand the forces imposed during shifting. They are engineered to be flexible yet durable, providing consistent performance over time. These cables consist of an outer housing and an inner wire, which work together to transmit the motion needed for gear engagement. The quality of these cables directly affects the transition between gears, impacting not only the vehicle's performance but also the driver's experience.

The Role of Manufacturers

Gear shift cable manufacturers play a pivotal role in ensuring that vehicles operate efficiently and safely. Their responsibilities include designing, producing, and testing these cables to meet rigorous industry standards. High-quality manufacturing processes result in reliable products that reduce the likelihood of failures and mitigate risks associated with shifting complications.

1. Research and Development Manufacturers invest significantly in R&D to innovate and enhance cable designs. They explore new materials and technologies to improve strength, flexibility, and resistance to wear and tear. This drives advancements in performance, contributing to better fuel efficiency and overall vehicle reliability.

2. Quality Control Ensuring quality is a fundamental aspect of gear shift cable manufacturing. This involves rigorous testing protocols, including tensile strength tests and fatigue tests, to ascertain that the cables can withstand the demands of real-world driving conditions. Manufacturers that adhere to strict quality control processes build trust with automakers and consumers alike.

gear shift cable manufacturers

3. Customization Different vehicle models require specific cable designs to function correctly. Manufacturers work closely with automakers to provide customized solutions that meet the unique specifications of each vehicle. This collaboration is essential for the development of aftermarket cables that fit various models, ensuring that replacement parts maintain the same quality and performance as the original.

4. Sustainability Practices As the automotive industry shifts towards sustainability, manufacturers are increasingly adopting eco-friendly practices. This includes using recyclable materials, reducing waste during production, and implementing energy-efficient manufacturing processes. Consumers are becoming more eco-conscious, and manufacturers that prioritize sustainability practices can position themselves favorably in the market.

Market Trends and Challenges

The demand for manufacturing gear shift cables is influenced by several key trends in the automotive sector, including the rise of electric vehicles (EVs) and advancements in automatic transmission systems. As EVs become more prevalent, the design and functionality of gear shift cables must adapt. Manufacturers need to innovate continually to meet the unique requirements of new drivetrain technologies.

However, challenges persist in the industry. Global supply chain disruptions, fluctuating raw material costs, and increasing competition from low-cost manufacturers pose significant hurdles. To maintain competitive advantage, reputable manufacturers focus on optimizing their supply chains, investing in automation, and enhancing operational efficiency.

Conclusion

In summary, gear shift cable manufacturers play an indispensable role in the automotive industry, ensuring the smooth and reliable operation of vehicles. Their commitment to innovation, quality control, and customer collaboration drives advancements in vehicle performance and safety. As the industry evolves, these manufacturers will continue to face challenges but also possess opportunities to thrive in an ever-changing landscape. By focusing on sustainable practices and developing tailored solutions, they can not only meet the demands of today’s automotive market but also contribute to a more efficient and environmentally friendly future.

-

Upgrade Your Vehicle with High-Quality Handbrake CablesNewsNov.01,2024

-

Optimize Your Bike's Performance with Quality CablesNewsNov.01,2024

-

Enhance Your Vehicle's Performance with Quality Clutch ComponentsNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality Throttle CablesNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality CablesNewsNov.01,2024

-

Affordable Solutions for Your Cable NeedsNewsNov.01,2024