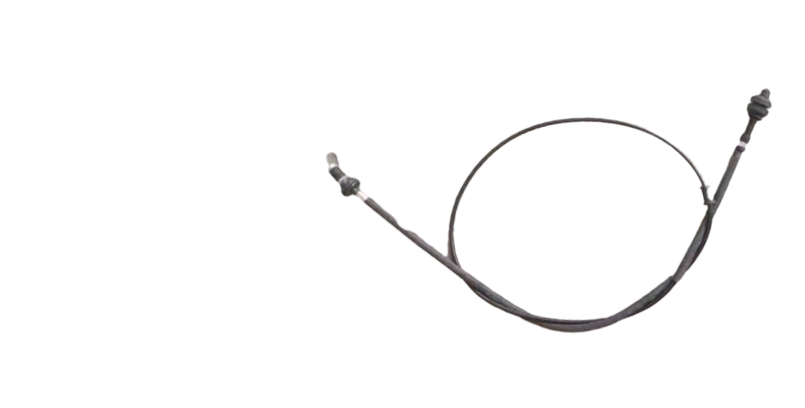

gear wire price

Understanding Gear Wire Prices Factors Influencing Cost and Market Trends

The gear wire market is a pivotal segment within the larger industrial wire sector, offering significant insights into manufacturing and mechanical engineering. Gear wires are integral components used in various applications, such as automotive, aerospace, and machinery, where durability and precision are paramount. Understanding gear wire prices is essential for manufacturers, engineers, and procurement specialists as it directly influences production costs and project budgeting.

Several factors contribute to the pricing of gear wires. Among them, the type of material used is perhaps the most influential. Gear wires are typically crafted from high-quality steel alloys, often treated to enhance their strength and flexibility. The presence of additives such as chromium, molybdenum, or nickel can significantly affect costs. For instance, stainless steel gear wires tend to be more expensive than their carbon steel counterparts due to the inherent corrosion resistance and additional processing required.

In addition to material costs, the manufacturing process plays a crucial role in determining gear wire prices. Production methods vary, ranging from cold drawing to heat treatment, each requiring different levels of investment in machinery and labor. Cold drawn gear wires, known for their enhanced dimensional accuracy and surface finish, typically command a premium price. Conversely, standard production processes may yield lower costs but could compromise on quality and performance, affecting the final pricing structure.

gear wire price

Market dynamics also heavily influence gear wire prices. Supply and demand fluctuations, driven by changes in the automotive or aerospace industries, can lead to significant price variations. For example, a surge in electric vehicle production may increase the demand for specific gear wires, consequently driving up prices. Conversely, an economic downturn could result in decreased demand, prompting manufacturers to lower their prices to remain competitive.

Moreover, global economic factors such as tariffs, trade regulations, and import/export restrictions can impact costs. Geopolitical tensions can disrupt supply chains, leading to scarcity of raw materials and, ultimately, higher prices for consumers. As manufacturers navigate these complex market conditions, price stability becomes a challenging objective.

Technological advancements also play a role in gear wire pricing. Innovations in production techniques and materials science can lead to more cost-effective methods of manufacturing gear wires. Companies that invest in cutting-edge technology may achieve higher efficiency and lower production costs, allowing them to offer competitive pricing. However, the initial investment in such technologies can be substantial, often reflected in the prices of the final product.

In conclusion, gear wire prices are influenced by a myriad of factors, including material selection, manufacturing processes, market dynamics, global economic conditions, and technological advancements. For manufacturers and procurement specialists, staying informed about these trends and factors is essential for making strategic purchasing decisions. As industries evolve and new technologies emerge, it is crucial to engage in continuous market analysis to understand pricing fluctuations and ensure competitiveness in the ever-evolving industrial landscape. Understanding the intricacies of gear wire pricing not only aids in budgeting but also enhances overall project success, pushing the boundaries of innovation in engineering and manufacturing.

-

Upgrade Your Vehicle with High-Quality Handbrake CablesNewsNov.01,2024

-

Optimize Your Bike's Performance with Quality CablesNewsNov.01,2024

-

Enhance Your Vehicle's Performance with Quality Clutch ComponentsNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality Throttle CablesNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality CablesNewsNov.01,2024

-

Affordable Solutions for Your Cable NeedsNewsNov.01,2024