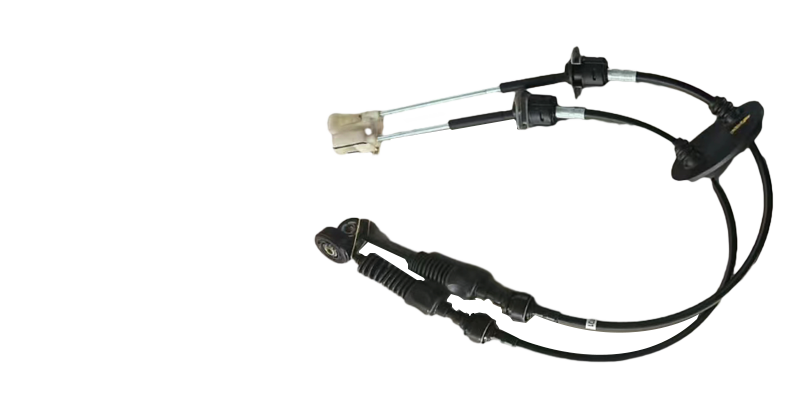

Hand Throttle Control - Optimal Performance and Precision

Hand Throttle Control A Comprehensive Overview

Hand throttle control is an essential feature in various applications, from motorcycles and agricultural machinery to industrial equipment and even some automobiles. Understanding its operation, benefits, and potential drawbacks can provide valuable insights for both enthusiasts and professionals alike.

At its core, hand throttle control allows the operator to manage engine speed and power output manually. Unlike standard pedal controls that require the driver to use their foot, the hand throttle is typically operated using a lever or grip mounted on the handlebars or dashboard. This design offers a unique flexibility, particularly in situations where precision and constant control of the engine speed are paramount.

One common application of hand throttle control is in motorcycles and ATVs. Riders often use this feature to maintain a steady speed while navigating varying terrains, ensuring that they have consistent power at their fingertips. In off-road situations, where sudden changes in elevation or obstacles are frequent, being able to adjust speed without using the foot can enhance the rider's focus and control over the vehicle.

Agricultural machinery also benefits greatly from hand throttle control. Many tractors and harvesters are equipped with this feature to help farmers adjust engine speeds while performing tasks such as tilling, planting, or harvesting crops. By allowing operators to stabilize power output, hand throttle control can lead to more precise work, reducing the chances of damage to crops or the equipment itself.

hand throttle control

In industrial settings, hand throttle control is often found on cranes and hoists, where fine-tuning the lifting speed is crucial. This feature permits operators to lift heavy loads smoothly and safely, offering better control and minimizing the risk of accidents. In such environments, the ability to maneuver with precision can greatly impact productivity and safety.

However, while hand throttle control offers numerous advantages, it is not without its challenges. Improper use can lead to engine strain, especially if the operator maintains high RPMs for extended periods. Additionally, the reliance on hand-operated controls can pose a risk in scenarios that require quick foot activation, such as in emergency situations where an immediate response is necessary. Operators must be adequately trained to use hand throttle systems effectively to mitigate these risks.

Another consideration is the ergonomic design of the hand throttle. The comfort and accessibility of the throttle mechanism are crucial, as factors such as grip strength and finger fatigue can affect its usability, particularly during prolonged operation. Manufacturers are continually improving designs to make hand throttle controls more user-friendly and adaptable to the specific needs of various applications.

In conclusion, hand throttle control is a versatile and beneficial feature across a range of vehicles and machinery. By allowing operators to finely tune engine speed with their hands, it offers enhanced control and safety in diverse situations. As technology evolves, the effectiveness and design of hand throttle systems will likely continue to improve, making them an invaluable aspect of modern machinery and transport. Educating users on best practices and operational techniques will further ensure that this feature is utilized to its fullest potential, optimizing performance and safety across the board.

-

Upgrade Your Vehicle with High-Quality Handbrake CablesNewsNov.01,2024

-

Optimize Your Bike's Performance with Quality CablesNewsNov.01,2024

-

Enhance Your Vehicle's Performance with Quality Clutch ComponentsNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality Throttle CablesNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality CablesNewsNov.01,2024

-

Affordable Solutions for Your Cable NeedsNewsNov.01,2024