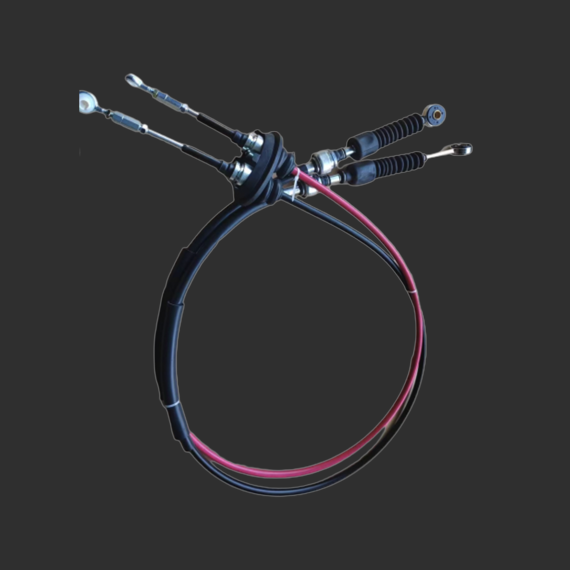

Manual Throttle Cable - Precision Control for Your Vehicle

Understanding Manual Throttle Cables A Comprehensive Guide

Manual throttle cables are essential components in many vehicles and machinery, particularly in older or more traditional models. Unlike modern electronic throttle control systems, manual throttle cables operate via a direct mechanical connection between the accelerator pedal and the throttle body. This article delves into the importance, functionality, and maintenance of manual throttle cables.

What is a Manual Throttle Cable?

A manual throttle cable is a strong yet flexible wire housed inside a protective sheath. One end is connected to the accelerator pedal, while the other is attached to the throttle body of the engine. When the driver presses the accelerator pedal, the cable pulls or pushes the throttle plate, allowing more air to enter the engine and, consequently, increasing power and speed.

The Functionality of Manual Throttle Cables

The simplicity of the manual throttle cable system offers several advantages, the most notable being immediate responsiveness. This mechanical linkage allows for direct control, giving drivers a tactile connection that can enhance the driving experience. Moreover, the reduction in complexity means fewer electronic components that can fail, resulting in increased reliability in specific applications.

Applications

Manual throttle cables are prevalent in various applications beyond traditional vehicles. They are commonly found in boats, motorcycles, lawn mowers, and industrial equipment. In these scenarios, where robustness and simplicity are essential, throttle cables provide dependable performance.

Common Issues with Manual Throttle Cables

manual throttle cable

Despite their reliability, manual throttle cables can encounter issues over time. Common problems include fraying or breaking of the cable, binding due to dirt or corrosion within the sheath, or improper adjustment leading to erratic throttle responses. Regular inspection is crucial to identify these issues before they become serious problems.

Maintenance Tips

To ensure the longevity and functionality of a manual throttle cable, regular maintenance is essential. Here are some key tips

1. Inspection Routinely check the cable for signs of wear, fraying, or kinking. If the cable appears damaged, it should be replaced immediately.

2. Cleaning Keep the cable and its housing clean. Dirt and grime can accumulate and cause binding, affecting throttle response.

3. Lubrication Apply a suitable lubricant to the cable to minimize friction and prevent corrosion. However, be cautious not to over-lubricate, as this can attract more dirt.

4. Adjustment Ensure the cable is properly adjusted. A cable that is too tight can lead to premature wear, while one that is too loose can cause throttle lag.

Conclusion

Understanding and maintaining manual throttle cables is vital for any driver or operator reliant on this mechanical system. Though technology continues to advance, the simplicity, effectiveness, and direct feedback provided by manual throttle cables remain invaluable. Regular inspections and maintenance can help ensure that your throttle system functions smoothly, enhancing both safety and performance. Whether in an automobile or specialized equipment, a well-maintained manual throttle cable is a key component of reliable operation.

-

Upgrade Your Vehicle with High-Quality Handbrake CablesNewsNov.01,2024

-

Optimize Your Bike's Performance with Quality CablesNewsNov.01,2024

-

Enhance Your Vehicle's Performance with Quality Clutch ComponentsNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality Throttle CablesNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality CablesNewsNov.01,2024

-

Affordable Solutions for Your Cable NeedsNewsNov.01,2024