Master Cylinder Clutch Line Maintenance and Performance Tips for Optimal Vehicle Function

The Master Cylinder Clutch Line An Overview

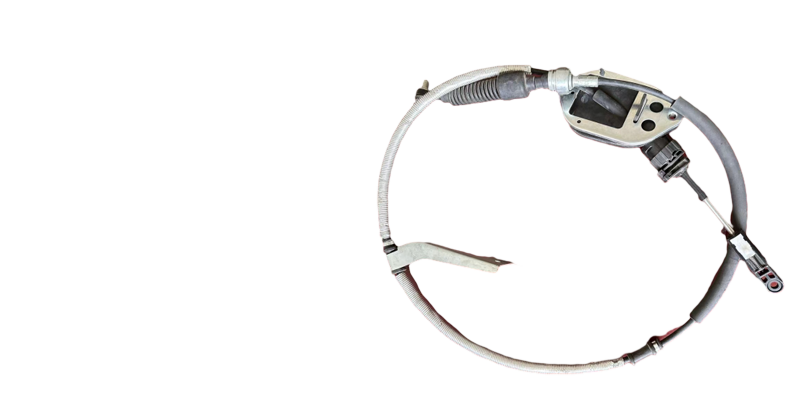

The master cylinder clutch line is an essential component of a vehicle's hydraulic clutch system. It plays a crucial role in transferring force from the clutch pedal to the clutch mechanism, ensuring smooth and effective vehicle operation. This article delves into the function, construction, maintenance, and potential issues associated with the master cylinder clutch line.

Function of the Master Cylinder Clutch Line

The primary function of the master cylinder is to create hydraulic pressure. When a driver presses the clutch pedal, it pushes a piston within the master cylinder. This pressure is then conveyed through the clutch line to the slave cylinder, which ultimately engages or disengages the clutch. This hydraulic system provides several advantages over mechanical linkages, such as reduced effort in pedal operation and more precise control of clutch engagement.

Construction of the Master Cylinder Clutch Line

The master cylinder typically consists of several components, including the reservoir, piston, and housing. The reservoir holds the hydraulic fluid, which is usually brake fluid. The piston, when actuated by the clutch pedal, compresses the fluid and generates the necessary pressure. The clutch line, made of high-pressure steel or rubber tubing, connects the master cylinder to the slave cylinder, ensuring the safe and effective transmission of hydraulic fluid.

The design of the clutch line itself is critical. It must withstand high pressures without bursting, and it should be resistant to wear and chemical damage. In high-performance vehicles, upgraded master cylinder clutch lines may be used to enhance responsiveness and durability.

Maintenance of the Master Cylinder Clutch Line

master cylinder clutch line

Regular maintenance of the master cylinder clutch line is essential for optimal performance. Drivers should regularly check the hydraulic fluid level in the reservoir and inspect the clutch line for any signs of leaks or damage. Brake fluid absorbs moisture over time, which can lead to corrosion and system failure if not replaced periodically.

Flushing the hydraulic system is another key maintenance task. Over time, contaminants can accumulate in the system, affecting performance. A thorough flush with fresh hydraulic fluid will help maintain the system's efficiency and ensure that the clutch operates smoothly.

Common Issues

Several common issues can arise with the master cylinder clutch line. One of the most prevalent problems is fluid leaks. Leaks can occur at various points, including the master cylinder, slave cylinder, or along the clutch line itself. A drop in hydraulic fluid can lead to a lack of pressure, resulting in a malfunctioning clutch that either fails to disengage or becomes hard to engage.

Air trapped in the hydraulic system can also cause problems. Air bubbles can compress under pressure, making the clutch feel spongy and unresponsive. Bleeding the system to remove trapped air is a necessary process to ensure proper function.

Another issue can be related to wear and tear on the master cylinder itself. Over time, the piston seals can degrade, leading to fluid bypass and a lack of pressure. In such cases, rebuilding or replacing the master cylinder may be necessary to restore proper functionality.

Conclusion

The master cylinder clutch line is a vital component in ensuring the effective operation of a vehicle's hydraulic clutch system. Understanding its function, proper maintenance, and common issues can empower drivers to keep their vehicles running smoothly. Whether you're a seasoned mechanic or a DIY enthusiast, staying informed about the master cylinder and its clutch line will lead to improved performance and longevity of your vehicle. Regular checks and timely repairs can prevent minor issues from becoming major problems, ensuring that your driving experience remains safe and enjoyable.

-

Upgrade Your Vehicle with High-Quality Handbrake CablesNewsNov.01,2024

-

Optimize Your Bike's Performance with Quality CablesNewsNov.01,2024

-

Enhance Your Vehicle's Performance with Quality Clutch ComponentsNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality Throttle CablesNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality CablesNewsNov.01,2024

-

Affordable Solutions for Your Cable NeedsNewsNov.01,2024