throttle cable manufacturers

Throttle Cable Manufacturers Ensuring Precision and Performance

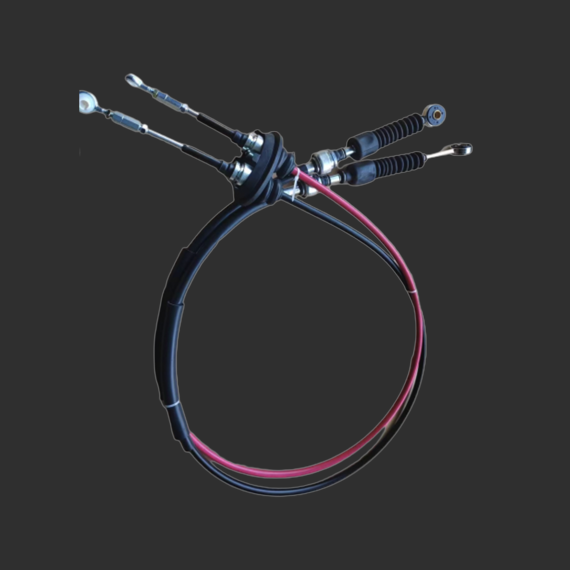

The automotive and machinery industries heavily rely on various components to ensure efficiency and safety, and one critical part that often goes unnoticed is the throttle cable. This essential component connects the accelerator pedal to the engine, controlling the amount of air and fuel mixture that enters the engine and ultimately affecting the vehicle's performance. As such, the demand for high-quality throttle cables has led to the emergence of several specialized throttle cable manufacturers.

Throttle cable manufacturers focus on producing cables that offer durability, flexibility, and resistance to wear and tear. One of the key factors contributing to the performance of a throttle cable is the material used in its construction. High-performance throttle cables are often made from stainless steel, which provides resistance to corrosion and fatigue. Additionally, the inner lining of the cable housing may be crafted from advanced polymers to reduce friction and ensure smooth operation, which is imperative for responsive throttle control.

Quality control is paramount in the manufacturing process of throttle cables. Leading manufacturers employ stringent testing protocols to ensure that each throttle cable meets the necessary specifications and performs as expected. They must adhere to industry standards and regulations, which often include rigorous testing for tensile strength, flexibility, and overall durability. This commitment to quality assurance not only enhances the reliability of their products but also instills confidence in consumers and automotive manufacturers alike.

throttle cable manufacturers

Another crucial aspect of throttle cable manufacturing is innovation. As vehicle technology continues to evolve with the advent of electric and hybrid vehicles, manufacturers are adapting to meet the challenges posed by these new technologies. This may involve developing cables that can withstand higher temperatures or cables equipped with advanced features, such as integrated sensors. Such innovations are vital as they align with the industry’s push towards enhanced performance and efficiency.

Moreover, the global market for throttle cable manufacturers is expanding, driven by the increasing production of automobiles and machinery worldwide

. Manufacturers are establishing better supply chain networks and exploring new markets, which helps in promoting competition and improving product offerings. Many companies are now focusing on customization, allowing manufacturers to obtain cables tailored specifically to their vehicle model or machinery requirements.The importance of effective communication between throttle cable manufacturers and their clients cannot be overstated. By fostering strong partnerships, manufacturers can better understand customer needs, which ultimately leads to the development of more effective solutions. Many reputable manufacturers offer extensive consultation services, helping clients select the right cables based on their specific applications, whether for performance vehicles, standard cars, or industrial machinery.

In conclusion, throttle cable manufacturers play an essential role in the automotive and machinery sectors, providing vital components that ensure optimum performance and safety. With ongoing innovations, stringent quality control measures, and a focus on customization, these manufacturers are well-positioned to meet the growing demands of the industry. As technology advances, the relationship between manufacturers and clients will continue to evolve, ultimately leading to refined products and a more efficient end-user experience. Whether for high-performance racing or everyday driving, the quality of throttle cables is paramount, as it directly influences vehicle responsiveness and operational efficiency.

-

Upgrade Your Vehicle with High-Quality Handbrake CablesNewsNov.01,2024

-

Optimize Your Bike's Performance with Quality CablesNewsNov.01,2024

-

Enhance Your Vehicle's Performance with Quality Clutch ComponentsNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality Throttle CablesNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality CablesNewsNov.01,2024

-

Affordable Solutions for Your Cable NeedsNewsNov.01,2024