Understanding in-line clutches and their applications in modern machinery and automotive systems

In-Line Clutch The Unsung Hero of Mechanical Systems

In various mechanical systems, clutches play a pivotal role in controlling the power transmission between different components. Among the array of clutch designs, the in-line clutch stands out as a significant innovation, particularly in applications where space is a constraint and efficiency is paramount. This article delves into the functionality, advantages, and applications of in-line clutches, highlighting their importance in modern engineering.

Understanding In-Line Clutches

An in-line clutch is designed to engage and disengage power transmission in a straight line, or in-line, configuration. Unlike traditional clutches, which may require more complex mechanisms, in-line clutches provide a straightforward solution for connecting and disconnecting shafts or gears in a compact space. The design typically involves two rotatable components that are aligned directly with one another, allowing for smoother engagement and disengagement compared to offset or angled clutch systems.

The operational principle of an in-line clutch revolves around friction or electromagnetic forces. When engaged, the clutch transmits torque from the driving shaft to the driven shaft, allowing the connected machinery to function. When disengaged, the flow of power is interrupted, enabling the operator to stop the driven component without affecting the driving system. This feature is crucial in many applications, as it improves control and prevents potential damage to machinery during operations.

Advantages of In-Line Clutches

1. Space Efficiency One of the most significant advantages of in-line clutches is their compact design. In-line clutches can fit into tighter spaces, making them ideal for applications where every inch of space counts. This characteristic is especially beneficial in automotive engineering, robotics, and aerospace applications where weight and space constraints are critical.

2. Simplicity and Reliability The straightforward design of in-line clutches contributes to their reliability. With fewer moving parts compared to more complex systems, the risk of mechanical failure is reduced. This simplicity also leads to easier installation and maintenance, which can save time and reduce operational costs over the life of the equipment.

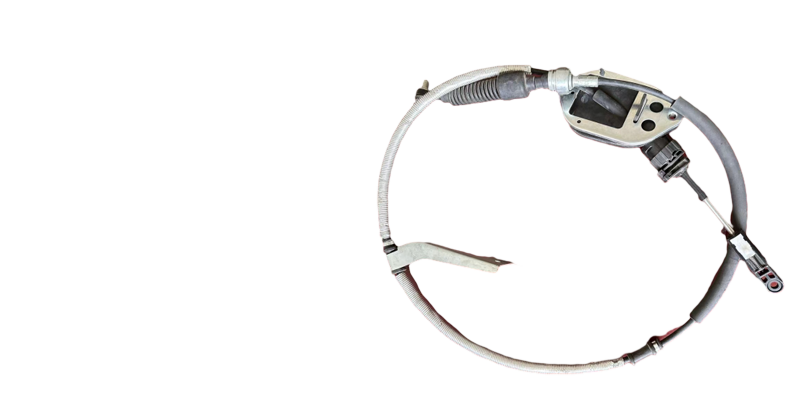

in line clutch

3. Smooth Operation In-line clutches are known for providing smooth engagement and disengagement. This feature is vital in applications such as vehicles and industrial machines, where abrupt changes in power can lead to mechanical stress and potential failures. Smooth transitions minimize wear and tear on components, extending their operational life.

4. Versatile Applications The versatility of in-line clutches means they can be found in a wide range of applications. They are commonly used in automotive transmissions, robotics, and conveyor systems, as well as in electric motors where precise control is required.

Applications of In-Line Clutches

In-line clutches are widely utilized across various industries. In the automotive sector, they are often found in automatic transmissions, allowing for seamless gear changes. In industrial machinery, they help facilitate operations in assembly lines, ensuring that conveyor systems can start and stop efficiently without disrupting the flow of production.

Moreover, in-line clutches are integral to robotic systems, where they allow for precise control over movement and torque application. This capability is essential for robotic arms that perform delicate tasks, necessitating gradual adjustments rather than sudden stops or starts.

Conclusion

In conclusion, in-line clutches serve as crucial components in many mechanical systems, offering space efficiency, simplicity, smooth operation, and versatility. As technology continues to advance, the importance of in-line clutches is likely to grow, further establishing them as the unsung heroes in the arena of power transmission and mechanical engineering. Understanding their role can lead to better design choices and more efficient machinery, highlighting the need for continued innovation in clutch technology.

-

Upgrade Your Vehicle with High-Quality Handbrake CablesNewsNov.01,2024

-

Optimize Your Bike's Performance with Quality CablesNewsNov.01,2024

-

Enhance Your Vehicle's Performance with Quality Clutch ComponentsNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality Throttle CablesNewsNov.01,2024

-

Elevate Your Vehicle's Performance with Quality CablesNewsNov.01,2024

-

Affordable Solutions for Your Cable NeedsNewsNov.01,2024